I. Product Overview

1. YZRW series eddy current brake wound rotor three-phase asynchronous motor for crane and metallurgy is composed of YZR series motor and eddy current brake mounted on its auxiliary shaft extension. It integrates two functions of drive and speed regulation: The utility model has the advantages of stable low-speed speed regulation characteristics, no runaway, reliable operation and the like.

2. Eddy current brake motor can operate normally under the following environmental conditions:

(1) The temperature of the cooling medium does not exceed 60 ° C (motors with Class H insulation) or 40 ° C (motors with Class F insulation);

(2) The altitude does not exceed 1000m;

(3) Frequent significant mechanical vibration and shock.

3. Eddy current brake motor is a derivative product of humid tropical climate environment. The winding and surface protective layer of the motor are specially impregnated and treated, except for the provisions in Article (2), and can operate normally under the following environmental conditions.

(1) At 25 ° C, the monthly average high relative humidity in wet months is 90%;

(2) Low ambient air humidity-15℃;

(3) Frequent starting and braking.

4. Rated power of eddy current brake motor under reference working system, rotor moment of inertia Jm1, open-circuit voltage of rotor winding, rated braking torque and limited braking torque of eddy current brake, and corresponding relationship between armature moment of inertia Jm2 and frame number shall comply with provisions in the following table.

| frame number | 112M | 132M1 | 132M2 | 160M1 | 160M2 | 160L | 180L | 200L | 225M | 250M1 | 250M2 | 280S | 280M | ||

| Eddy current brake motor |

1000 r/min |

Power KW |

1.5 | 2.2 | 3.7 | 5.5 | 7.5 | 11 | 15 | 22 | 30 | 37 | 45 | 55 | 75 |

|

Jm1 Kg.m2 |

0.03 | 0.06 | 0.07 | 0.12 | 0.15 | 0.2 | 0.39 | 0.67 | 0.84 | 1.52 | 1.78 | 2.35 | 2.86 | ||

|

rotor open circuit VoltageV |

100 | 132 | 185 | 138 | 185 | 250 | 218 | 200 | 250 | 250 | 290 | 280 | 370 | ||

|

750 r/min |

Power KW |

- | - | - | - | - | 7.5 | 11 | 15 | 22 | 30 | 37 | 45 | 55 | |

|

Jm1 Kg.m2 |

- | - | - | - | - | 0.20 | 0.39 | 0.67 | 0.82 | 1.52 | 1.79 | 2.35 | 2.86 | ||

|

rotor open circuit Voltage V |

- | - | - | - | - | 205 | 172 | 178 | 232 | 272 | 335 | 305 | 360 | ||

|

600 r/min |

Power KW |

- | - | - | - | - | - | - | - | - | - | - | 37 | 45 | |

|

Jm1 Kg.m2 |

- | - | - | - | - | - | - | - | - | - | - | 3.58 | 3.98 | ||

|

rotor open circuit Voltage V |

- | - | - | - | - | - | - | - | - | - | - | 150 | 172 | ||

| Eddy current brake motor | eddy current brake |

rated braking moment N·m |

7 | 18 | 64 | 118 | 170 | 235 | 390 | 590 | |||||

|

rated speed r/min |

100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |||||||

|

limited braking moment N·m |

26 | 64 | 196 | 245 | 390 | 540 | 785 | 1180 | |||||||

|

Jm2 kg·m2 |

0.13 | 0.3 | 0.6 | 1.3 | 1.9 | 2.9 | 5.3 | 8.8 | |||||||

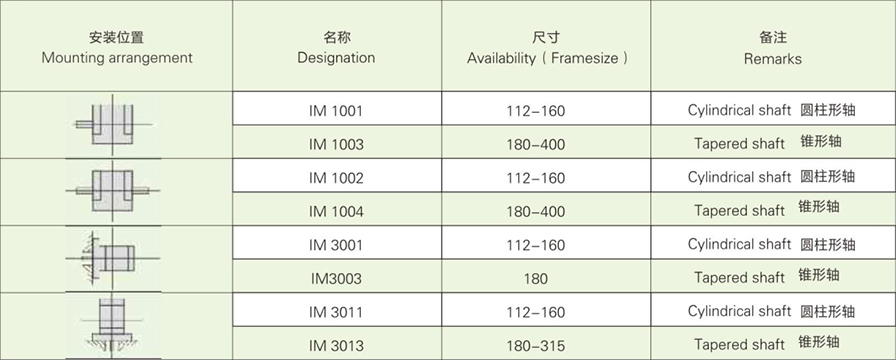

5. The structure and installation form of eddy current brake motor are IM1001, IM1003, IM3011 and IM3013, and manufactured according to the following table:

| Structure and installation form | code name | Manufacturing range (frame number) |

|

IM1001 | 112~160 |

| IM1003 | 180~280 | |

|

IM3011 | 112~160 |

| IM3013 | 180~280 |

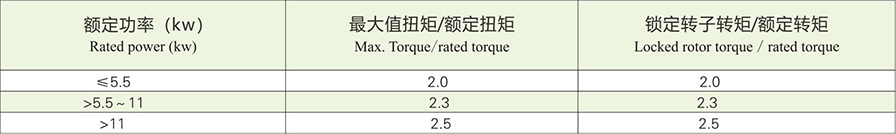

6. Under rated voltage and reference working system, the ratio of large torque to rated torque of eddy current brake motor shall not be lower than the specifications in the following table:

| ≤5.5 | 2.3 |

| >5.5~11 | 2.5 |

| >11 | 2.8 |

1. Product Description

1.1 YZR and YZ series are of the latest design,featuring large overload capacity and high mechanical strength,and especially suitable for driving various types of metallurgical machines and cranes and/or other similar equipments.YZR series is wound-rotor motor and YZ series is cage motor.

1.2 The motors can run normally under following ambient conditions:

(1) Temperature of cooling medium not exceeding 60 (for motors for metallurgical purpose)or 40℃ (for motors for crane purpose)

(2) Elevation not exceeding 1000m

(3) Constant/frequent and noticeable mechanical vibration and shock

1.3 The motors can work normally under following loading conditions:

(1) Starting and reversing frequently

(2) Frequent electric or mechanical braking

1.4 Rated frequency of the motors is 50Hz,and rated voltage is 380V

1.5 Connection:the stator winding is connected in Y for 132kW and below,and G for the rest

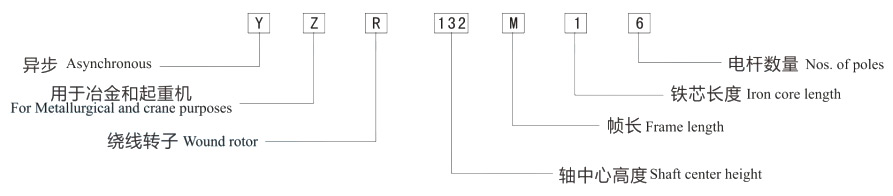

1.6 Type Designation

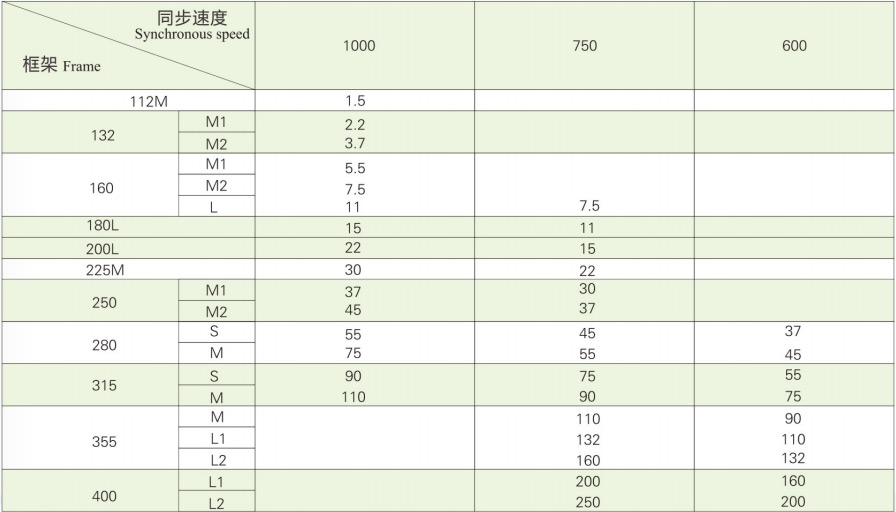

1.7 Output power speed

The range of rated output and synchronous speed for the basic duty type (S,40%)are shown in tablel. (cage motor manufacturing,specifications in thick-line block)Table(2)

1.8 For the YZR series motors,when working with basic duty type,the guaranteed values of the ratio of the maximum torque to the rated torque under rated voltage are given in Table 2.

1.9 For YZ series motors,when working with basic duty type,the guaranteed values of the ratio of the maximum torque and the locked rotor torque to the rated torque under rated voltage are given in table 3.

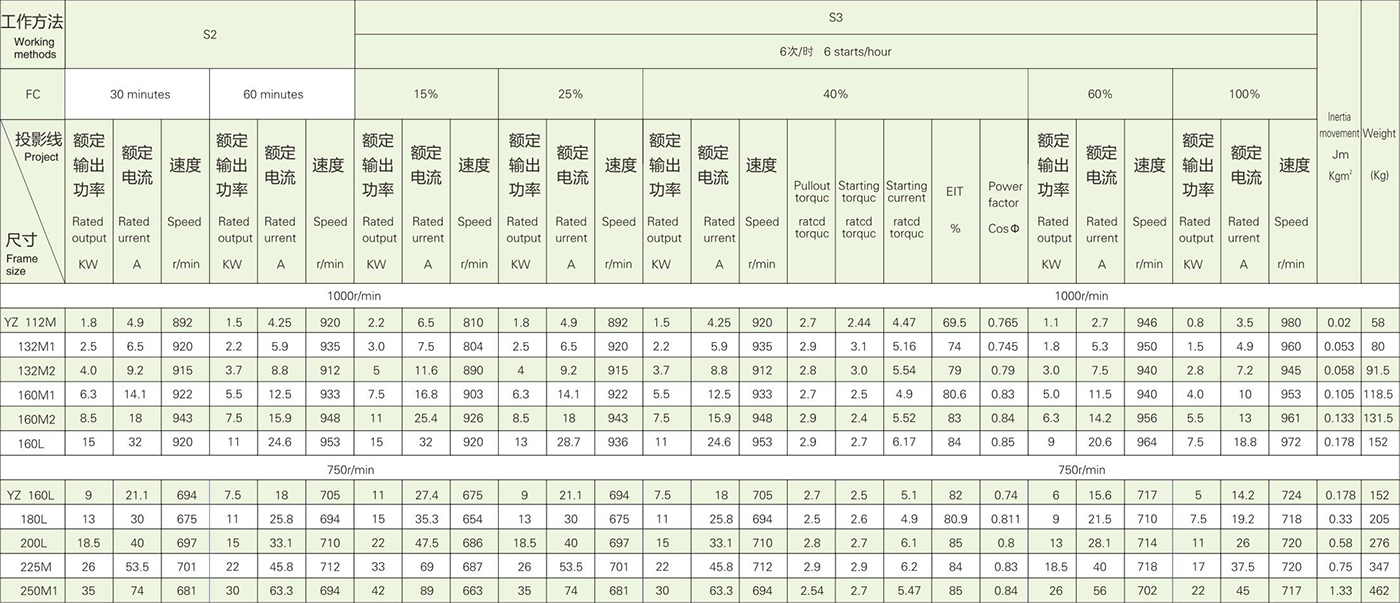

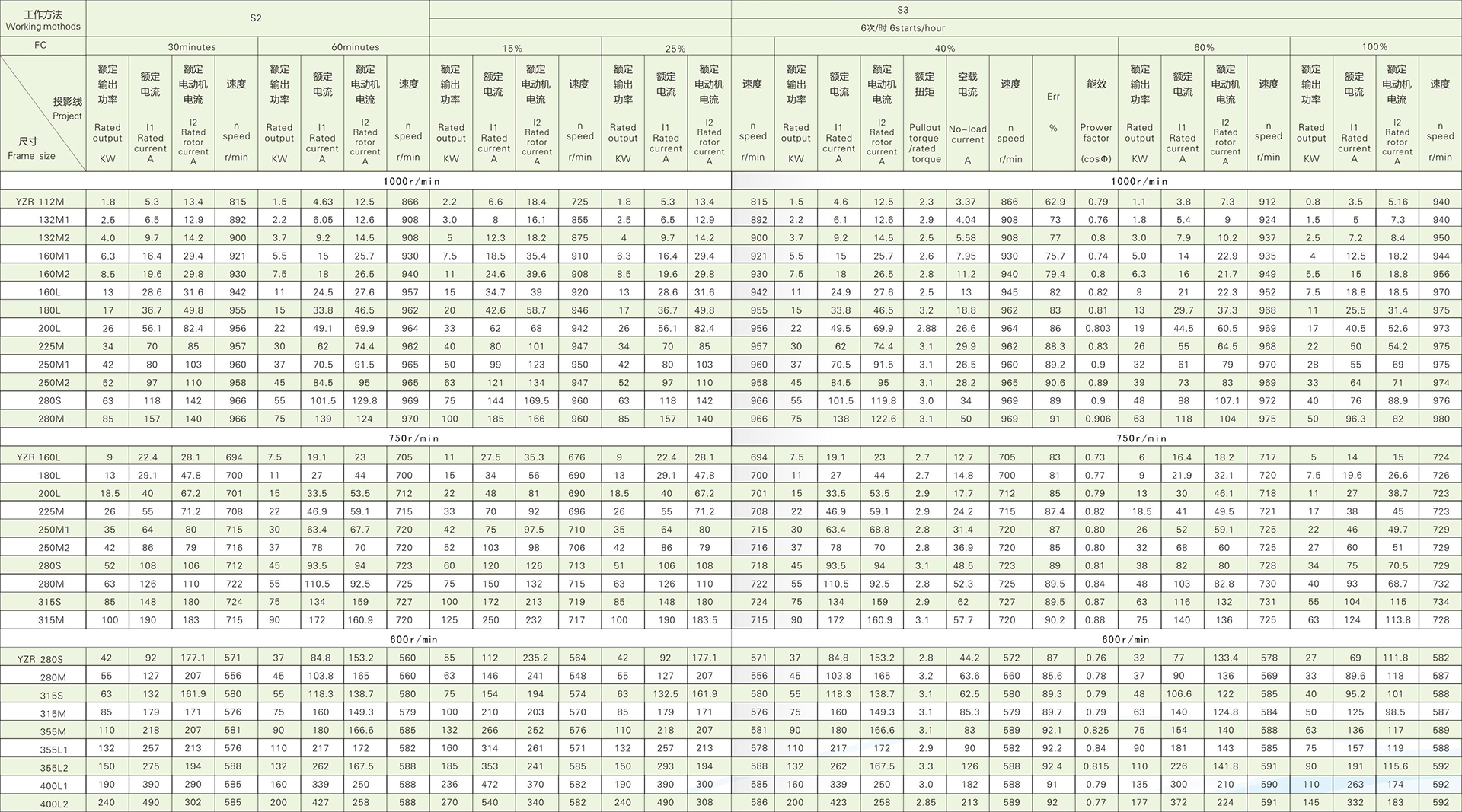

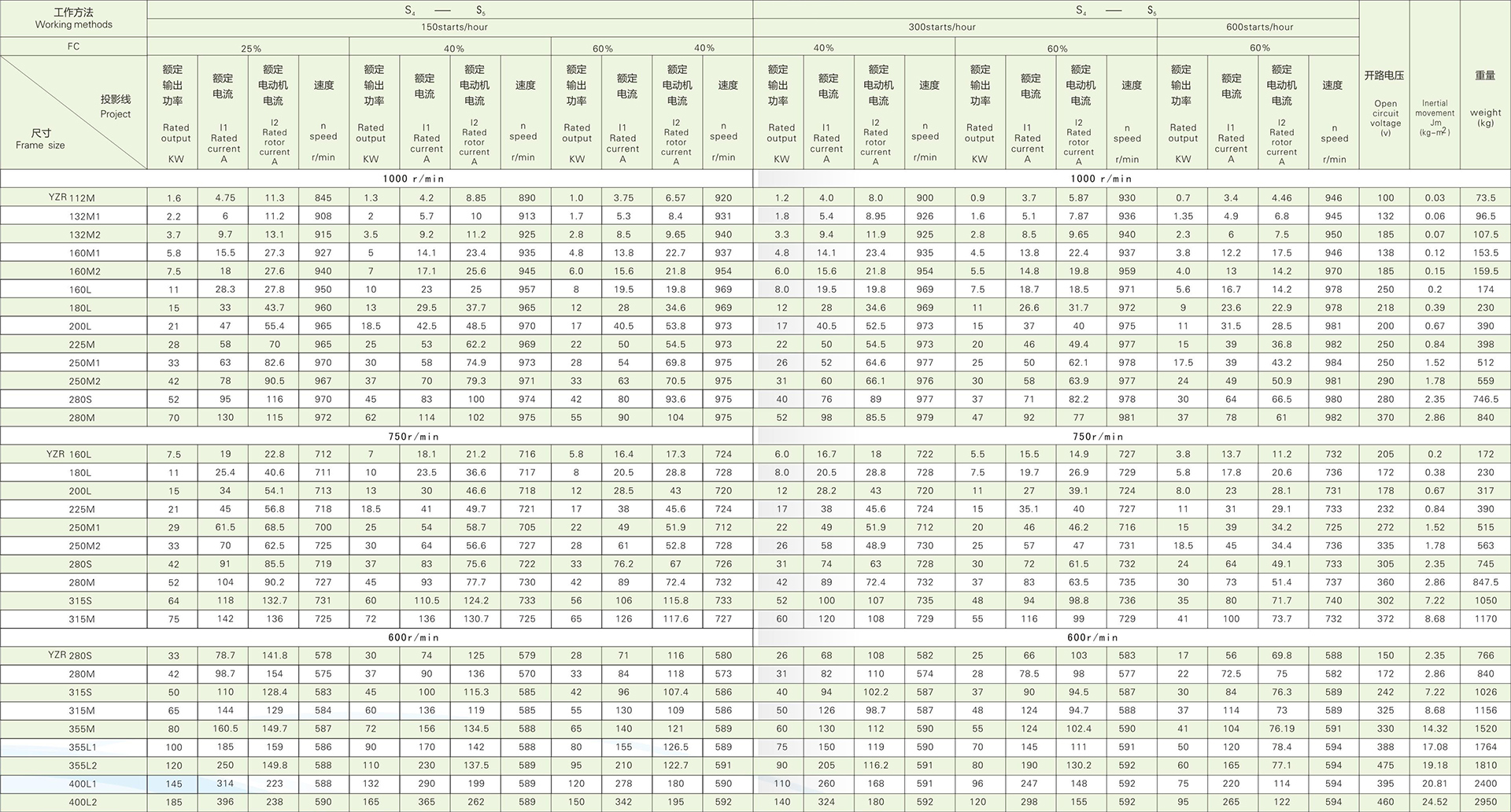

2. Motor works and technical parameter

2.1 For the motors,rated voltage is 380V and rated frequency is 50Hz.

2.2 The motors are suitable for intermittent periodic loading.Depending on different loadings,there are following duty types:

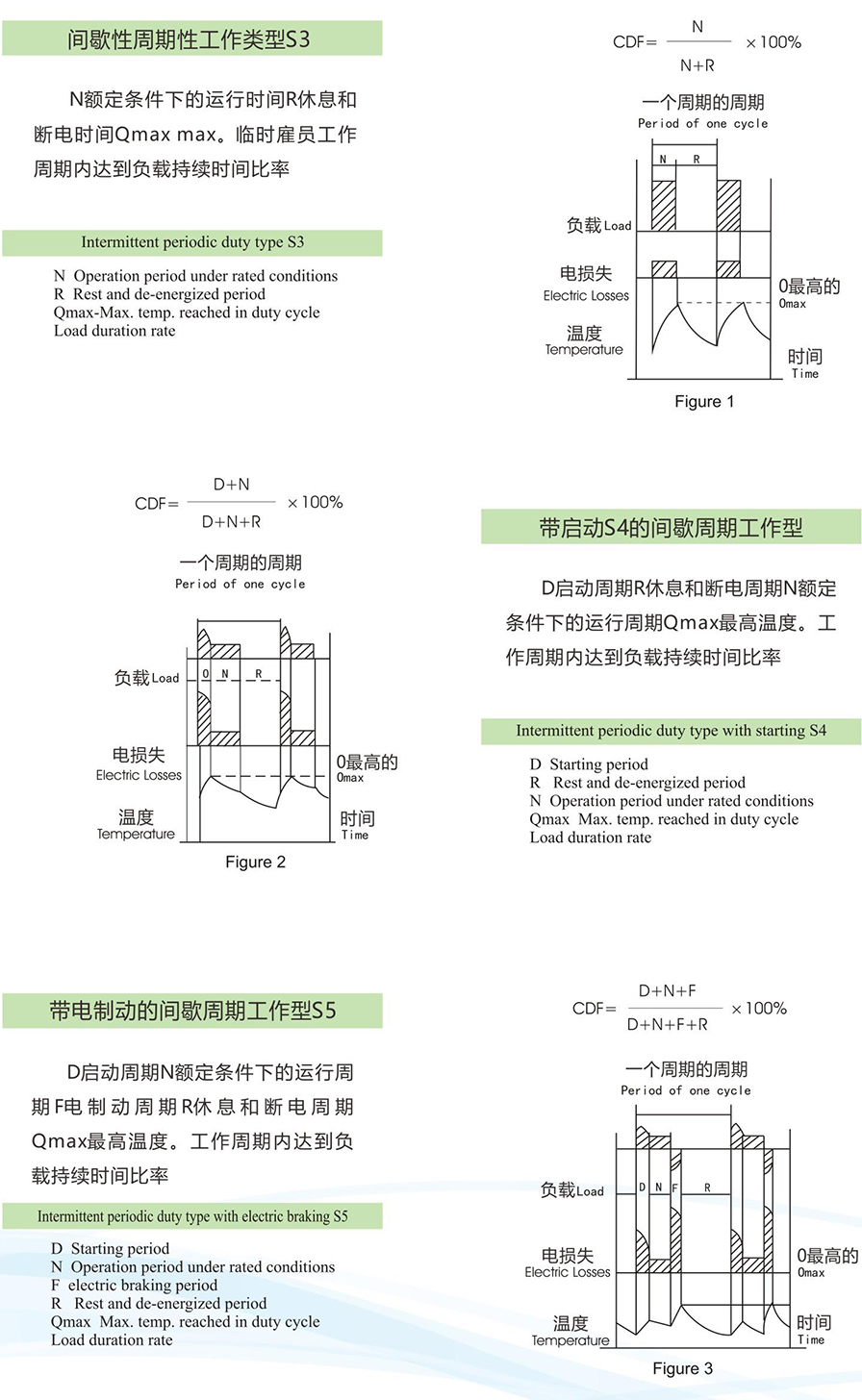

2.2.1 Intermittent periodic duty type(S3)It is a sequence of identical duty cycles,each including a period of operation at constant load and a rest and de-energized period (see Fig.1). In this duty type,the starting current of each cycle does not significantly affect the temperature rise of motor: every 10 minutes taken as one cycle,i.e.,starting 6 times per hour.

2.2.2 Intermittent periodic duty type with starting(S4) A sequence of identical duty cycles,each including a significant period of starting,a period of operation of constant load and a rest and de-energized period (see Fig.2).Starting times per hour are 150,300 and 600.

2.2.3 Intermittent periodic duty type with electric braking(S5)It is a sequence of identical duty cycles,each consisting of a period of starting,a period of operation at constant load,a quick electric braking period and a rest and de- energized period (see Fig.3).

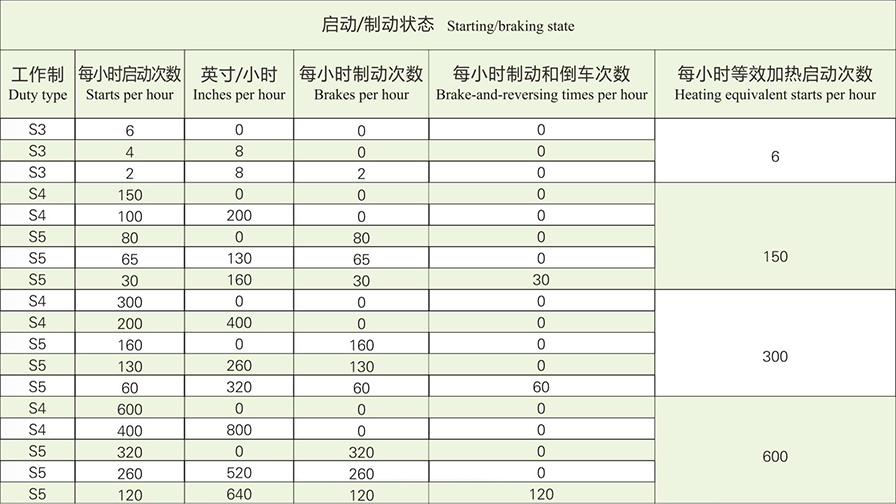

2.3 When selecting the motors,different kinds of starting and braking states need to be reduced,as per the equivalent heating,into the equivalent starting times,which is then used to determine the rating of motor.Typical reduction example is shown in Table 4.

Reduction method:

Inching (the final speed being not exceeding 25%of rated speed)four times is equivalent to starting once. Electrical braking(being braked to 1/3 rated speed)once is equivalent to 0.8 times a start.

2.4 The basic duty type for the motors is S3-400.See Table 5 for technical data for each duty type.Information on nameplate of motor is generally provided as per basic duty type,and customized information is also possible.It is necessary to consult the manufacturer if the motors need to run in duty types other than S2~S5.

Motor works and technical parameter Table(5-1)

Motor works and technical parameter Table(5-2-1)

Motor works and technical parameter Table (5-2-2)

3. Motor structure

3.1 Insulation class

Motors have two insulation classes,namely,F class and H class.F class is suitable where cooling medium temperature does not exceed 40C,while H class is suitable where cooling medium temperature does not exceed 60C.Motors with either insulation class have identical electric behavior as the motors with the other one do.

3.2 Degree of protection

The degree of protection is IP44 for general-purpose motors and IP54 for metallurgical-purpose motors.

3.3 Cooling method

For frame size 112132,natural cooling,(IC0041),for frame size 160355,built-in fan cooling (ICO141). For frame size 400,external-fan cooling with internal circulating ventilation,(IC0151)

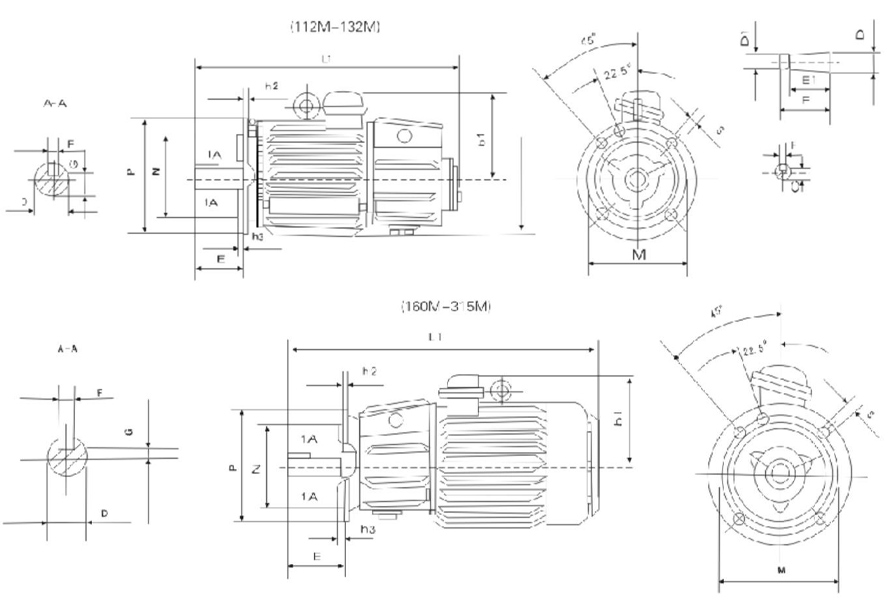

3.4 For construction and mounting arrangements,see Table 6

3.5 Shaft extension is available upon user's sizes or requirements.

3.6 Type of drive:Motors are designed for coupling or spur gear drive.When spur gear drive is used,the pitch diameter of the pinion should not be less than twice of that of the shaft extension

3.7 The Junction box for the stator is fitted on the top of the frame,and it is possible to make connection on either side of the frame.For the rotor,it is possible to make connection on either side of the cover.

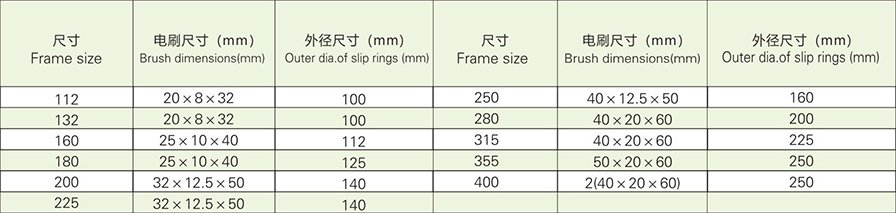

3.8 Brush type is J201,and its specification is given in Table 7

3.9 For bearing type see Table 8

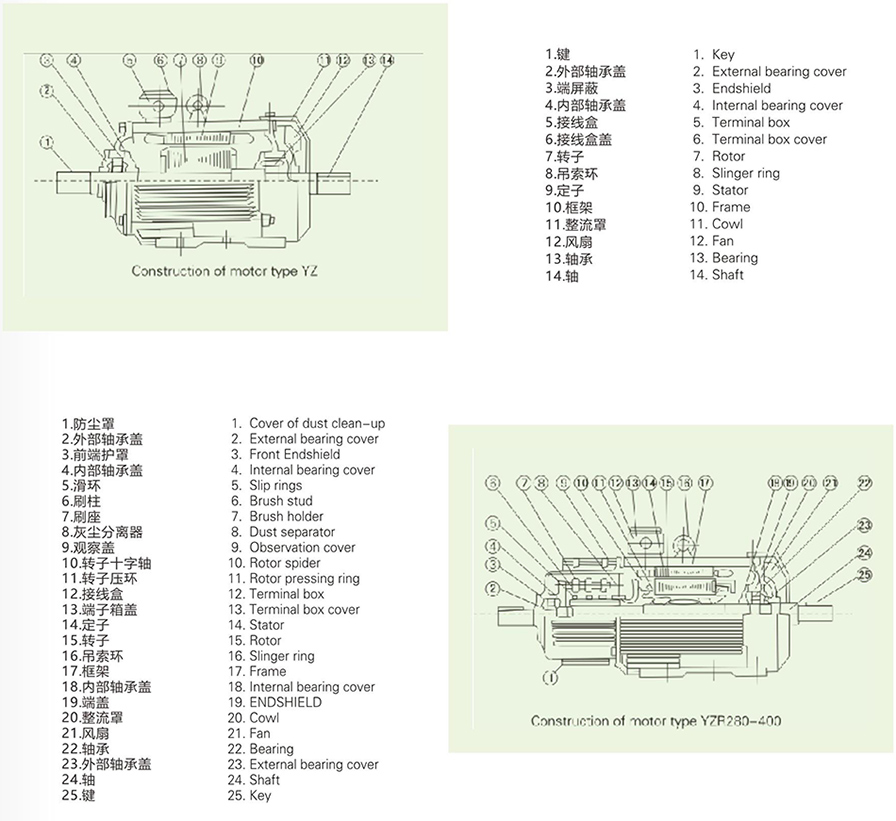

3.10 For names of parts of motor,see Fig.4

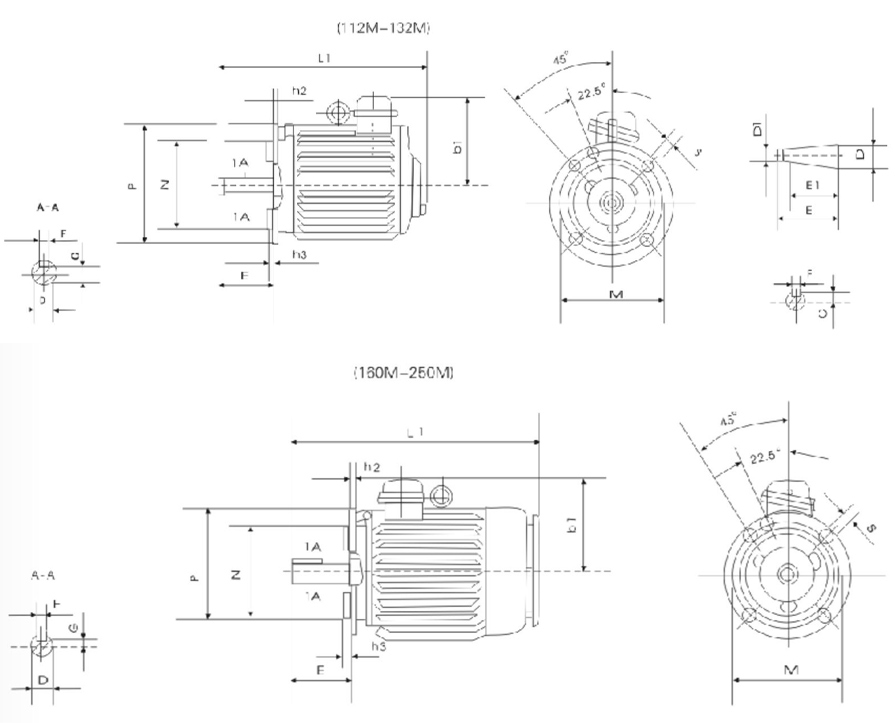

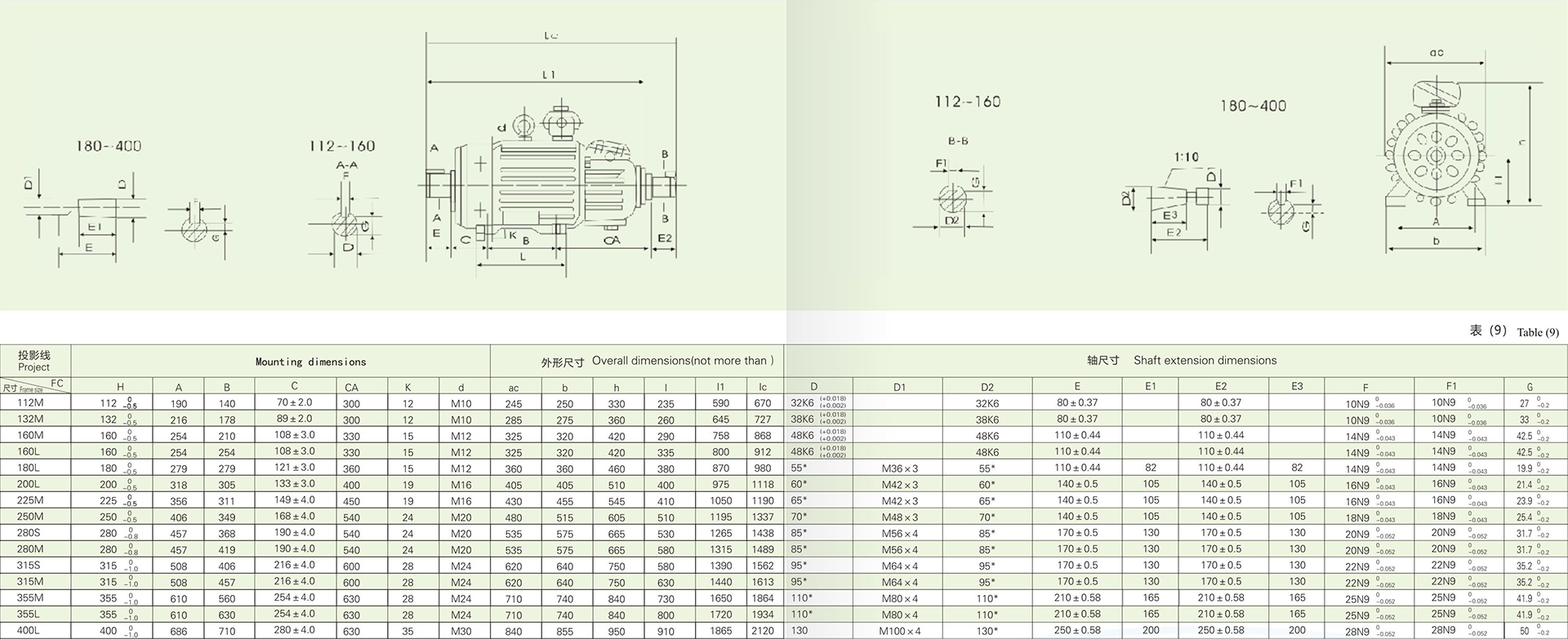

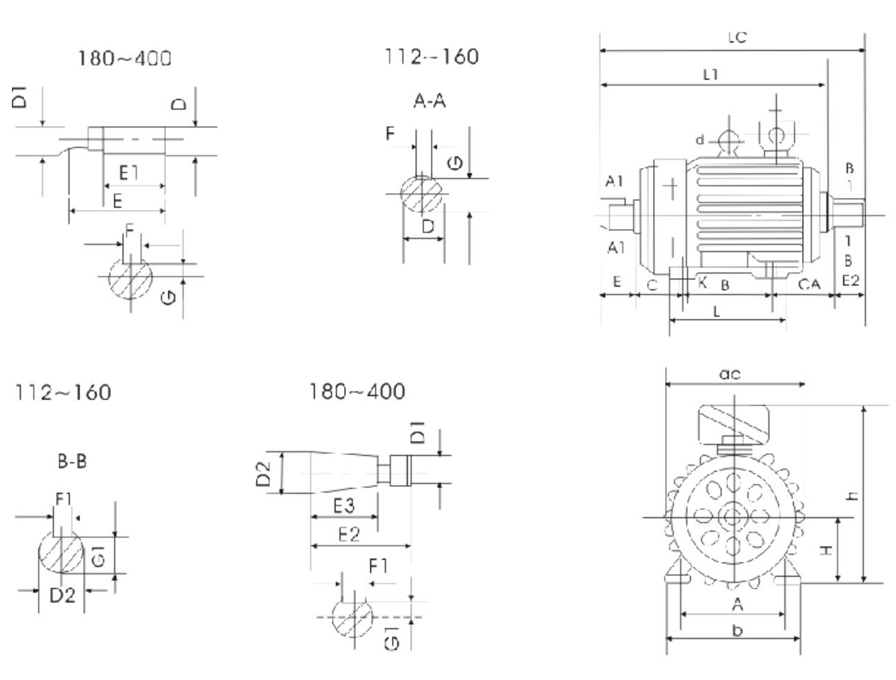

4 .Mounting overall dimensions

Table 9 YZR series IMl mounting overall dimensions

4.1 See Table 9 for overall mounting dimensions of YZR IMI 112-400

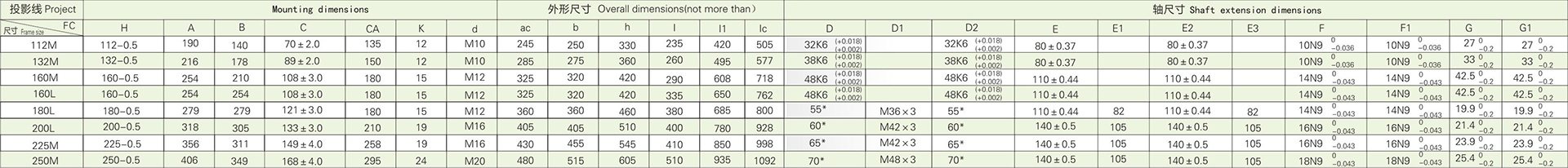

4.2 See Table 10 for overall mounting dimensions of YZ IMI 112-250

4.3 See Table 11 for overall mounting dimensions of YZR IM3 mounting mode

4.4 See Table 12 for overall mounting dimensions of YZ IM3 mounting mode

Table 10 YZ IMI series mounting overall dimensions

Table 11 YZR IM3001.IM3003 and IM3013 dimension table

Table12 YZ IM3001,IM3003 and Im3011,IM3013dimension table